Beautiful Tips About Why Do We Use Torque

Understanding Torque

1. What Exactly IS Torque?

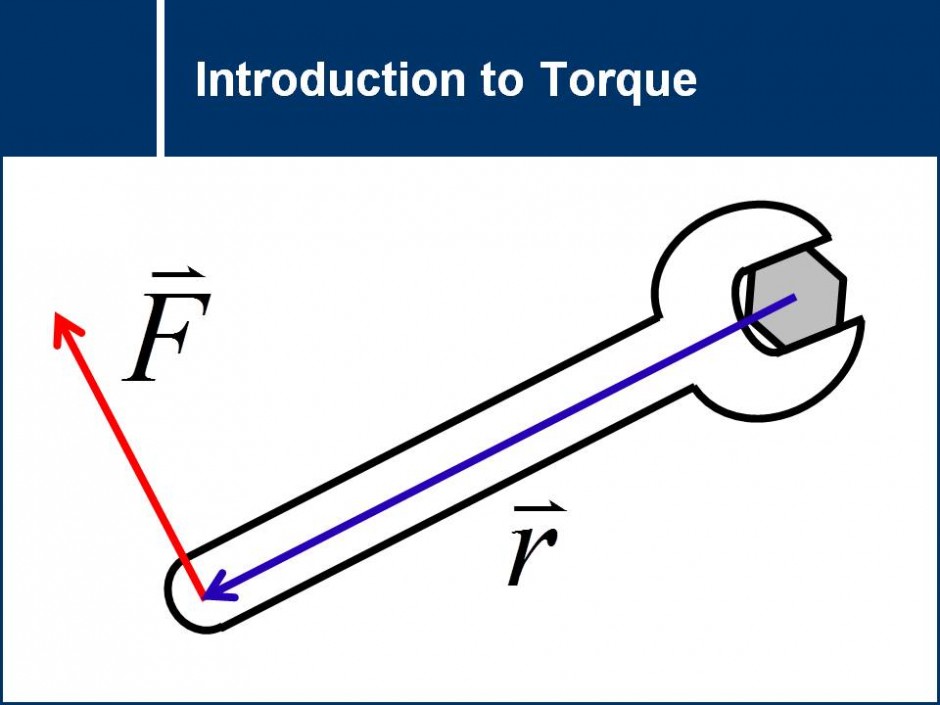

Ever wondered what makes a wrench turn a stubborn bolt or how an engine gets your car moving? The answer, in a nutshell (pun intended!), is torque. It's more than just spinning something; it's the rotational equivalent of a force. Think of it as the 'oomph' behind a twist. It's what lets you open that pickle jar that's been taunting you for weeks, or keeps a ceiling fan spinning smoothly on a hot summer day.

Torque isn't just about applying force; it's about where you apply it. Imagine pushing on a door right next to the hinges. It's tough to get it open, right? But if you push on the doorknob, further away from the hinges, it's much easier. That's because the distance from the pivot point (the hinges) affects the amount of torque you generate. The further away you push, the more rotational power you get.

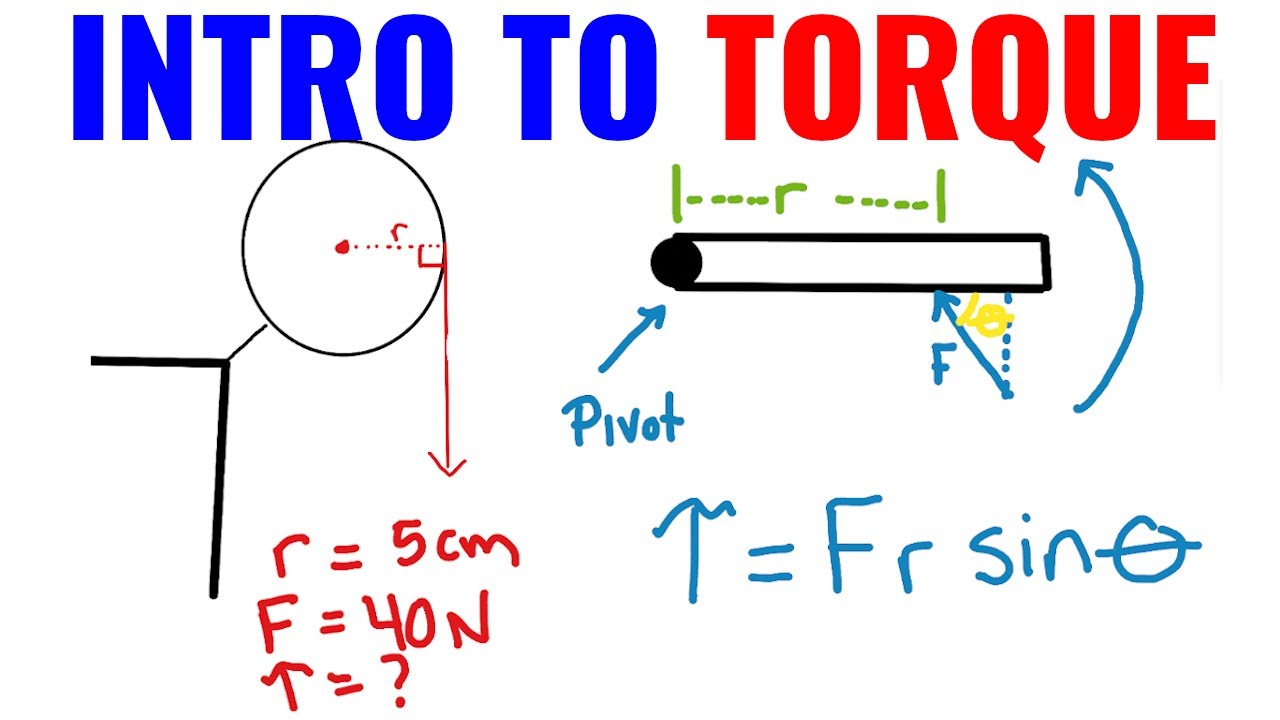

Mathematically speaking, torque is the product of the force applied and the distance from the axis of rotation (also known as the lever arm). So, even a small force can generate a significant amount of torque if the lever arm is long enough. This principle is used in countless applications, from simple hand tools to complex machinery.

Without torque, our world would be a very different place. Imagine trying to drive a car with an engine that only produced linear force, not rotational force. You'd just be...well, not going anywhere fast. Torque is the unsung hero of motion, working behind the scenes to make things spin, turn, and generally do all sorts of useful stuff.

How To Solve Torque Problems

Why is Torque so Darn Important, Anyway?

2. Beyond Just Turning Nuts and Bolts

Okay, so we know torque is about rotational force. But why is it so important that we use it as a fundamental concept in engineering and physics? Well, for starters, it's the driving force (again, pun intended!) behind almost any rotating system. Everything from the tiny motor in your electric toothbrush to the massive turbines in a power plant relies on torque to function.

Think about your car again. The engine produces torque, which is then transmitted through the transmission and axles to the wheels. That torque is what propels the car forward. The amount of torque an engine can produce directly affects its acceleration and its ability to climb hills. A high-torque engine will generally feel more powerful and responsive, especially at lower speeds.

In manufacturing, torque is critical for tightening fasteners like screws and bolts. Applying the correct amount of torque ensures that the joint is secure without being overtightened, which could damage the parts. Torque wrenches are used to precisely measure and control the amount of torque applied to a fastener, ensuring consistent and reliable results.

But torque isn't just about brute force. It's also crucial for precise control and delicate operations. For example, in robotics, torque is used to control the movements of robotic arms and joints. By carefully controlling the torque applied to each joint, robots can perform complex tasks with incredible precision.

Application Of The Cross Product Torque YouTube

Different Kinds of Torque

3. Static vs. Dynamic and Everything in Between

Just like there are different kinds of forces (think pushing, pulling, gravitational), there are also different types of torque, depending on the situation. The most basic distinction is between static and dynamic torque. Static torque is what you're dealing with when something isn't moving, like when you're trying to loosen a stuck bolt. You're applying force, but nothing's rotating... yet. Dynamic torque, on the other hand, is present when something is rotating, like the spinning shaft of an engine.

Beyond static and dynamic, you'll hear about breakaway torque. This is the torque needed to initiate movement from a standstill. Think about that stubborn bolt again. You need to apply a certain amount of force before it finally breaks free. Breakaway torque is usually higher than the running torque, which is the torque needed to keep something rotating once it's already moving.

There's also the concept of stalling torque, which is the maximum torque an electric motor can produce before it stalls (stops rotating). This is an important specification for selecting the right motor for a particular application. You need to make sure the motor can produce enough torque to overcome the load without stalling.

Understanding these different types of torque is essential for engineers and designers. It allows them to accurately predict how a system will behave and select the appropriate components for the job. Failing to consider these nuances can lead to all sorts of problems, from stripped bolts to catastrophic failures.

What Is Torque? Force & Leverage For Scientists And Engineers YouTube

Tools of the Trade

4. Wrenches, Sensors, and Clever Gadgets

So, how do we actually measure and apply torque in the real world? Well, there are a bunch of tools designed specifically for the job. The most common is the torque wrench. This is a wrench with a built-in mechanism that allows you to set a specific torque value. When you reach that value, the wrench will either click, slip, or provide a visual indication, letting you know you've applied the correct amount of torque.

There are different types of torque wrenches, each with its own advantages and disadvantages. Click-type torque wrenches are popular for their ease of use and affordability. Beam-type torque wrenches are known for their accuracy and durability. And electronic torque wrenches offer the highest level of precision and features, such as data logging and programmable settings.

But it's not just about wrenches! Torque sensors, also known as torque transducers, are used to measure torque in a wide range of applications, from automotive testing to aerospace engineering. These sensors typically use strain gauges to measure the deformation of a shaft under load, which is then converted into an electrical signal proportional to the torque.

Beyond these dedicated tools, torque is also a factor in the design of many everyday objects. Think about the design of a screwdriver handle. A larger diameter handle provides a longer lever arm, making it easier to apply torque to the screw. Even the shape of the handle can affect the amount of torque you can comfortably apply. It's all about maximizing efficiency and minimizing the risk of injury.

Torque in Everyday Life

5. From Opening Doors to Driving Cars

You might think that torque is only something engineers and mechanics worry about, but it's actually a fundamental part of our everyday lives. Every time you open a door, turn a faucet, or ride a bicycle, you're applying torque. It's so ingrained in our daily routines that we often don't even think about it.

Consider opening a door. You apply a force to the doorknob, which is located some distance from the hinges (the axis of rotation). That force, combined with the distance, creates torque, which rotates the door open. The further you are from the hinges, the less force you need to apply to achieve the same amount of torque. That's why doorknobs are typically placed near the edge of the door.

Or how about riding a bicycle? When you pedal, you're applying torque to the crank arms. This torque is then transmitted through the chain and gears to the rear wheel, propelling the bicycle forward. The gears allow you to adjust the amount of torque applied to the rear wheel, making it easier to climb hills or ride at high speeds.

Even something as simple as tightening a jar lid involves torque. You apply a rotational force to the lid, and if the torque is sufficient, the lid will seal properly. If you don't apply enough torque, the lid might leak. And if you apply too much torque, you might damage the lid or the jar. So, the next time you're struggling to open a stubborn jar, remember the power of torque!

FAQ

6. Your Burning Torque Questions Answered

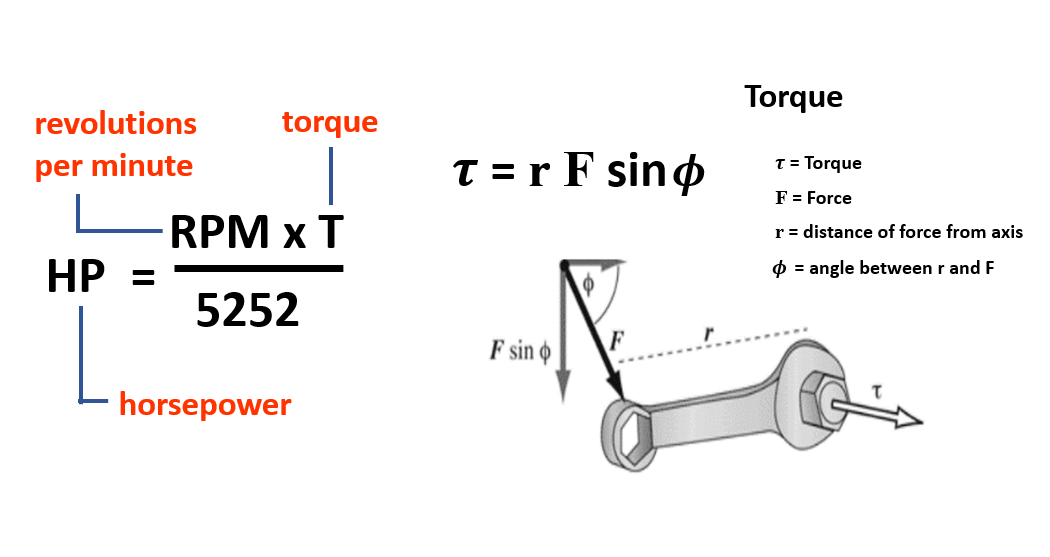

Q: What's the difference between torque and horsepower?A: Torque is a measure of rotational force, while horsepower is a measure of power, which is the rate at which work is done. Think of torque as the "grunt" and horsepower as the "speed." An engine with high torque can pull heavy loads, while an engine with high horsepower can accelerate quickly. Horsepower is directly related to torque and RPM (revolutions per minute). Horsepower = (Torque x RPM) / 5252. It's like saying torque is how well an engine works and horsepower is how fast it works.

Q: How can I increase torque?A: There are several ways to increase torque. One way is to increase the force applied. Another way is to increase the distance from the axis of rotation (the lever arm). In engines, increasing displacement (the size of the cylinders) or using forced induction (turbocharging or supercharging) can increase torque. Also, gearing can be used to trade speed for torque. A lower gear ratio provides more torque but less speed, while a higher gear ratio provides less torque but more speed.

Q: Is more torque always better?A: Not necessarily! It depends on the application. In some cases, too much torque can be detrimental. For example, overtightening a bolt can strip the threads or damage the parts being joined. In other cases, excessive torque can lead to instability or control problems. It's important to apply the appropriate amount of torque for the specific task at hand. You need the right amount of "oomph," not just all the "oomph."

Q: How do I choose the right torque wrench?A: Choosing the right torque wrench depends on the torque range you need to work with and the level of accuracy required. For low-torque applications, a beam-type or click-type torque wrench might be sufficient. For high-torque applications or applications where precision is critical, an electronic torque wrench is recommended. Also, consider the size and type of fasteners you'll be working with and choose a torque wrench with the appropriate drive size and sockets.

Q: Can I convert horsepower to torque?A: Yes, you can! Using the formula: Torque = (Horsepower x 5252) / RPM. Knowing any two of these values (horsepower, torque, RPM) allows you to calculate the third.