Neat Tips About How To Tell If A Circuit Board Is Bad

Circuit Analysis How To Repair A Burnt PCB? Electrical Engineering

Is Your Circuit Board Singing the Blues? How to Tell if It's Gone Bad

Okay, so your gadget isn't working. Maybe your coffee maker stubbornly refuses to brew, or your TV screen remains stubbornly black. Before you throw the whole thing out the window (we've all been there!), there's a chance the culprit is a faulty circuit board. These little guys, packed with components, are the brains behind much of our modern tech. But how do you know if it's truly gone belly up? Let's dive in and figure out how to diagnose a potentially defunct circuit board.

1. Visual Inspection

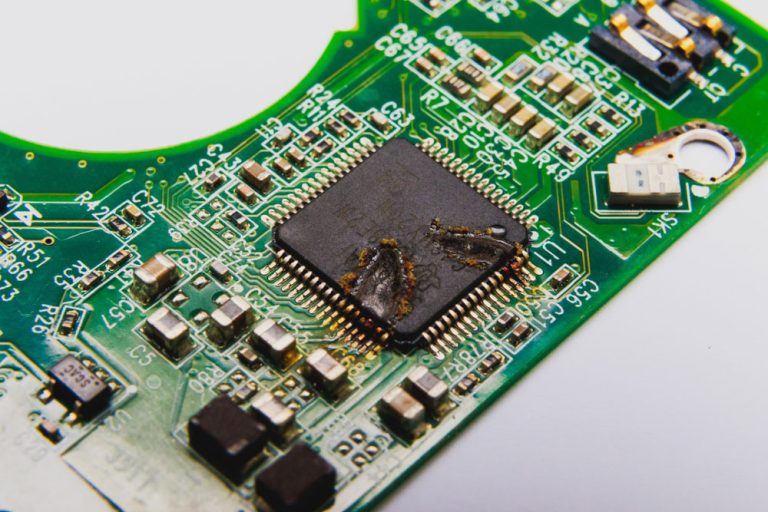

Think of this as the detective work of electronics repair. A thorough visual inspection can reveal some obvious issues. Look closely for any signs of damage. We're talking about things like bulging or leaking capacitors (they look like tiny cans), burnt resistors (charred bits are a dead giveaway), cracked solder joints (those shiny connection points), or even physical breaks in the board itself. It's like examining a crime scene for clues!

Pay special attention to areas near components that generate heat, like voltage regulators or power amplifiers. These spots are more prone to failure. Grab a magnifying glass if you have one — sometimes the damage is subtle. A strong flashlight can also help you see into shadows and highlight any irregularities on the circuit board's surface. Remember, a clear view is key to uncovering the truth!

Don't forget to check for corrosion! If the board has been exposed to moisture, you might see a green or white powdery substance forming on the components or traces. This is bad news and usually indicates significant damage. Corrosion can eat away at the metal and disrupt the flow of electricity. If you spot corrosion, clean it carefully with isopropyl alcohol and a soft brush, but be aware that the board may already be compromised.

Finally, sniff around (carefully, of course!). A burning smell is never a good sign, and it often indicates a component has overheated and failed. If you detect a burnt odor, it's highly likely that the circuit board is damaged and needs to be addressed. So trust your senses — they can lead you to the right solution.

My PC Keeps Turning Off... LTT Releases Linus Tech Tips

Power Up Problems

2. Testing for Basic Functionality

Let's assume your visual inspection didn't reveal anything obvious. The next step is to see if the circuit board powers up at all. If it's part of a larger device, does the device turn on? Are there any indicator lights that illuminate? If you get absolutely no signs of life, it could indicate a major failure in the power supply section of the circuit board.

However, before you jump to conclusions, double-check the power source itself. Is the power cord properly connected? Is the outlet working? Have you checked the fuse? Sometimes the problem is external to the circuit board, and it's an easy fix. A little bit of preliminary testing can save you a lot of time and effort in the long run.

If the device powers on but doesn't function correctly — for example, it displays an error message or only performs some of its functions — it suggests that a specific part of the circuit board is malfunctioning. This requires more targeted troubleshooting, which we'll get to later. In these cases, try to isolate which functions are affected to narrow down the potential problem area.

Also, listen carefully. Unusual noises, like buzzing, hissing, or crackling, can be a sign of a faulty component on the circuit board. These sounds often indicate arcing or short circuits, which can be dangerous. If you hear any strange noises, immediately disconnect the power and investigate further.

Repair Solder Joint On Circuit Board At Suzanne Prince Blog

Multimeter Magic

3. Getting Down to Brass Tacks with a Multimeter

A multimeter is an indispensable tool for diagnosing circuit board problems. It allows you to measure voltage, current, and resistance, which can help you pinpoint faulty components. Before you start probing around, familiarize yourself with your multimeter and how to use it safely. Always disconnect the power before taking any measurements.

Start by checking the voltage levels at various points on the circuit board. Compare your measurements to the expected values, which you can usually find in the device's service manual or online schematics. If a voltage is significantly lower or higher than it should be, it suggests a problem with the power supply or a component that's drawing too much current.

Next, test the resistance of resistors. Resistors are color-coded, and each color represents a specific resistance value. Use your multimeter to measure the resistance of each resistor and compare it to its expected value. If the measured resistance is significantly different, the resistor is likely faulty and needs to be replaced. A resistor can also open, in which case it will read as infinite resistance.

Capacitors can also be tested with a multimeter, but the process is a bit more complex. You can check for shorts by measuring the resistance across the capacitor's terminals. A low resistance reading indicates a shorted capacitor. You can also check for open circuits by measuring the capacitance using a multimeter with a capacitance measurement function.

Component Close-Up

4. Zeroing in on the Usual Suspects

Certain components are more prone to failure than others. Electrolytic capacitors, for example, have a limited lifespan and tend to dry out or leak over time. As we mentioned earlier, look for bulging or leaking capacitors as a sign of failure. Resistors can also burn out due to overheating or excessive current.

Integrated circuits (ICs), also known as chips, are complex components that can fail in various ways. Sometimes, they simply stop functioning. Other times, they can develop internal shorts or open circuits. Testing ICs can be tricky, but you can often use a multimeter to check for shorts between their pins. Also, if a specific IC is known to be problematic in a particular device, it's often worth replacing it as a first step in troubleshooting.

Transistors are another common source of failure. They can be tested with a multimeter to check for shorts or open circuits. You can also use a transistor tester to measure their gain, which indicates how well they amplify signals. A transistor with low gain may not be functioning properly.

Diodes are semiconductor devices that allow current to flow in only one direction. They can be tested with a multimeter to check for shorts or open circuits. You can also use a diode test function on your multimeter to measure their forward voltage drop, which should be around 0.7 volts for silicon diodes. If the forward voltage drop is significantly different, the diode is likely faulty.

How Do Circuit Boards Work? ABL Circuits

When to Call in the Pros

5. The Importance of Expertise

Troubleshooting circuit boards can be challenging, even for experienced technicians. If you're not comfortable working with electronics or if you don't have the necessary tools and knowledge, it's best to consult a professional. Attempting to repair a circuit board without proper training can be dangerous and can potentially damage the device further.

Also, some circuit boards are simply too complex to repair economically. In such cases, it may be more cost-effective to replace the entire board or the device itself. A qualified technician can assess the damage and provide you with a realistic estimate of the repair costs. They can also advise you on whether it's worth repairing the board or replacing it.

Furthermore, certain repairs require specialized equipment, such as soldering stations, hot air rework stations, and oscilloscopes. If you don't have access to these tools, you won't be able to perform certain repairs. So, knowing your limitations and seeking help when needed is crucial for ensuring a successful outcome and maintaining safety.

Finally, remember that safety is paramount. Always disconnect the power before working on any electronic device. Wear appropriate safety glasses to protect your eyes from flying debris. And never work on electronics in a wet or damp environment. By following these safety precautions, you can minimize the risk of accidents and injuries.