Heartwarming Info About Do Motors Need Pure Sine Wave

/europe--greece--2018--view-of-modified-sine-wave-inverter--12-volts-dc-230-volts-ac--965514438-5c4e004d46e0fb0001a8e7f3.jpg)

Pdjolo Blog

Unlocking the Secrets

1. Why All the Fuss About Sine Waves?

Okay, let's dive right in. You've probably heard whispers about "pure sine waves" and how essential they are for motors. But what's the big deal? A sine wave, in the electrical world, is basically the gold standard for AC power. Its a smooth, undulating curve representing voltage or current over time. Imagine a gentle ocean wave — that's your sine wave. But unlike the ocean, messing with this wave can actually cause some serious headaches for your motors. We want happy motors, don't we?

Think of it like this: A motor is designed to dance to the rhythm of a perfect sine wave. When the power source provides a distorted or "dirty" sine wave, it's like trying to dance to a song that keeps skipping. The motor will vibrate, overheat, and generally not be a happy camper. In some situations, this can significantly reduce the motor's lifespan. So, providing clean power helps to ensure reliable and efficient operation.

Modified sine waves, which are commonly used in cheaper inverters, attempt to approximate a sine wave but use a stepped or jagged form. While they might power some devices adequately, they often introduce harmonics (extra frequencies) into the electrical system. These harmonics cause extra heat and stress on the motor's windings.

Essentially, using a pure sine wave is like providing the motor with a premium fuel. The motor runs smoother, cooler, and lasts longer. It minimizes energy loss and reduces the risk of component failure. That means saving money in the long run by reducing maintenance costs and replacements.

Pure Sine Wave Vs Modified Square Simulated

Decoding the Motor Landscape

2. Not All Motors Are Created Equal

Now, here's where things get interesting. It's not a one-size-fits-all situation. Some motors are more sensitive to the quality of the power they receive than others. The type of motor and its application play a significant role in determining if a pure sine wave is mandatory or just a nice-to-have.

Induction motors, which are the workhorses of many industrial and household applications (think washing machines and fans), are generally more tolerant of modified sine waves. They're built to withstand some level of distortion. However, even with these robust motors, performance and longevity can be improved with a pure sine wave. The gains might not be dramatic, but they are there. It's similar to giving your car premium gasoline; it will probably run fine on regular, but the premium grade might improve performance and prolong engine life.

On the other hand, some motors are divas. Synchronous motors, especially those used in precision applications like timing devices and some industrial machinery, demand a pristine sine wave. They are extremely sensitive to harmonic distortion, which can cause them to malfunction or even become damaged. Think about high-precision medical equipment or robotics; you wouldn't want to risk using anything less than the best power source.

Brushless DC (BLDC) motors also often prefer pure sine wave, though their sensitivity depends on their design and the controller they use. The complexity of modern electronics inside these motors often means that they are best used with pure sine wave inverters. Essentially, deciding whether your motor needs a pure sine wave is like choosing the right tool for a job. Using the wrong tool might get the job done, but it might also cause damage or unnecessary wear and tear.

Pure Sine Wave Inverter Circuit Diagrams

The Dark Side

3. Harmonics, Heat, and Headaches

So, what happens when you feed a motor a diet of modified sine waves or other forms of distorted power? Well, let's just say it's not a pretty picture. Harmonic distortion is the primary culprit. These extra frequencies introduce unwanted currents into the motor windings, leading to increased heat and reduced efficiency.

Excessive heat is a motor's worst enemy. It degrades the insulation on the windings, which can eventually lead to short circuits and catastrophic failure. Think of it like constantly running a marathon without proper hydration. Eventually, your body will break down. Similarly, a motor subjected to continuous harmonic stress will eventually give out.

Beyond heat, distorted power can also cause increased vibration and noise. This is because the motor is struggling to maintain smooth rotation with an erratic power input. The mechanical stress created by the vibration can accelerate wear and tear on bearings and other components. So, it's not just about the electrical components; the entire motor suffers.

Finally, let's not forget about efficiency. Motors running on distorted power simply consume more energy to produce the same amount of work. This translates directly into higher electricity bills and a larger carbon footprint. So, using a pure sine wave isn't just good for the motor; it's good for your wallet and the environment too.

Pure Sine Wave Inverters

4. Investing in Motor Harmony

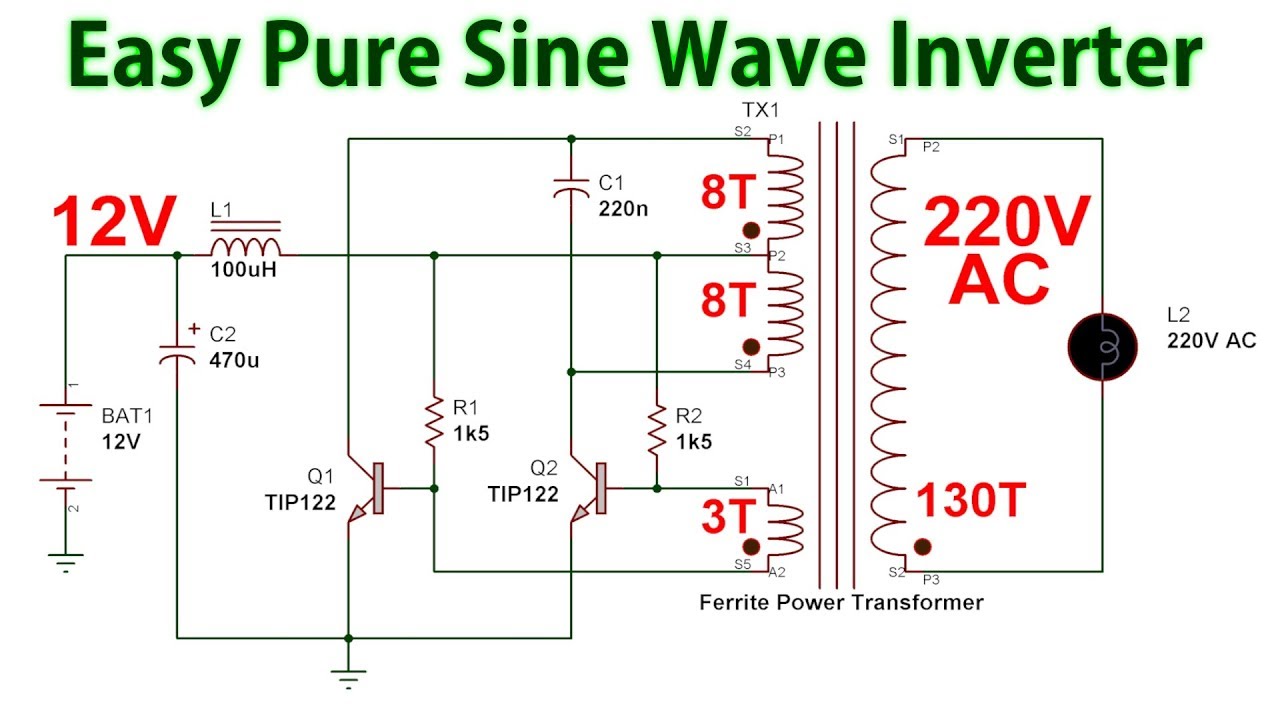

If you've determined that your motor needs a pure sine wave, the solution is simple: use a pure sine wave inverter. These inverters are designed to convert DC power (like from a battery) into a clean, smooth AC sine wave that your motor will love. They accomplish this by employing sophisticated electronic circuitry that generates the desired waveform with minimal distortion.

Now, pure sine wave inverters do come at a higher price point than their modified sine wave counterparts. However, the investment is often justified by the benefits they provide. Reduced motor wear, increased efficiency, and quieter operation can all contribute to long-term cost savings. Think of it as paying for a premium insurance policy for your motor; it might cost more upfront, but it can save you a lot of money in the long run.

When selecting a pure sine wave inverter, it's important to choose one that is properly sized for your motor. Overloading an inverter can lead to reduced performance and even damage. It's also crucial to consider the inverter's total harmonic distortion (THD) rating. A lower THD rating indicates a cleaner sine wave and better motor performance.

Modern pure sine wave inverters offer a range of features, including overload protection, short-circuit protection, and thermal shutdown. These features help to protect both the inverter and the motor from damage. They are a worthwhile investment to ensure reliable and long-lasting operation. So, think of these inverters as guardians for your motors protectors against the harsh realities of the electrical world.

![Modified Vs. Pure Sine Wave Power Inverters [Purchasing Guide] Modified Vs. Pure Sine Wave Power Inverters [Purchasing Guide]](https://samlexamerica.com/wp-content/uploads/2022/04/Sine-Wave_DC-AC_Diagrams-hero-04.png)

Modified Vs. Pure Sine Wave Power Inverters [Purchasing Guide]

Making the Call

5. Weighing the Pros and Cons

Ultimately, the decision of whether or not to use a pure sine wave inverter depends on a careful consideration of your specific needs and circumstances. If you are powering sensitive equipment or want to maximize the lifespan and efficiency of your motors, a pure sine wave inverter is definitely the way to go. The cost might seem high initially, but consider the long-term benefits.

However, if you are powering less sensitive devices or are on a tight budget, a modified sine wave inverter might suffice. Just be aware of the potential risks and limitations. The important thing is to make an informed decision based on your understanding of the technology and your specific application.

Do your research and understand the types of motors you're powering. Are they used in critical applications where downtime is unacceptable? Are they expensive to replace? Answering these questions will help you prioritize your needs and make the right choice. Remember, it's about finding the balance between cost, performance, and reliability.

In the end, choosing the right power source for your motors is like choosing the right ingredients for a recipe. Using high-quality ingredients will result in a better-tasting dish. Similarly, using a clean, pure sine wave power source will result in happier, healthier motors that last longer and perform better. And who doesn't want happy motors?

Solar Inverter 101 What Is A Jackery Australia

FAQs

6. Your Quick Guide to Sine Wave Sanity

Q: Will a modified sine wave inverter immediately destroy my motor?A: Not necessarily! Many motors can tolerate modified sine waves to some extent. However, prolonged use with distorted power can shorten their lifespan and reduce efficiency. Think of it as consistently eating junk food — you might not get sick immediately, but it's not good for you in the long run.

Q: How can I tell if my inverter is putting out a pure or modified sine wave?A: The easiest way is to check the inverter's specifications. Manufacturers typically advertise whether their inverters are pure or modified sine wave. You can also use an oscilloscope to visually inspect the waveform. If you see a smooth, undulating curve, it's a pure sine wave. If you see steps or jagged edges, it's a modified sine wave.

Q: Are pure sine wave inverters more efficient than modified sine wave inverters?A: Generally, yes. Pure sine wave inverters tend to be more efficient because they minimize the amount of energy lost due to harmonic distortion. This translates into lower electricity bills and a smaller carbon footprint. Plus, happy motors are efficient motors!