Ideal Info About How Do You Read Gauge Size

Decoding Gauge Sizes

1. What is Gauge Size, Anyway?

Ever stared blankly at a wire, needle, or even sheet metal description listing a "gauge" size and wondered what on earth it meant? You're not alone! Gauge size can seem like a secret code at first glance, but it's actually a fairly straightforward system once you understand the basics. Think of it like shoe sizes — seemingly random numbers that somehow tell you how big something is.

Essentially, gauge size is a numerical indication of the diameter or thickness of an object. This is commonly used for things like wires (electrical, guitar strings), needles (sewing, medical), and sheet metal. The catch? It's often an inverse relationship. This means a larger gauge number actually represents a smaller diameter or thickness. Confusing, I know! Let's dive deeper.

The whole "inverse" thing comes from the historical way wire was drawn. The gauge number corresponded to the number of times the wire had to be pulled through a draw plate to achieve the desired thickness. More pulls meant a smaller diameter, hence a higher gauge number. So, while technically the gauge isn't a direct measurement, it allows manufacturers and consumers to communicate effectively about size.

Don't panic! We'll break down how to interpret those mysterious numbers and put an end to the gauge-size-induced bewilderment. Think of it as learning a new language — wire-speak, needle-speak, sheet-metal-speak... you get the idea.

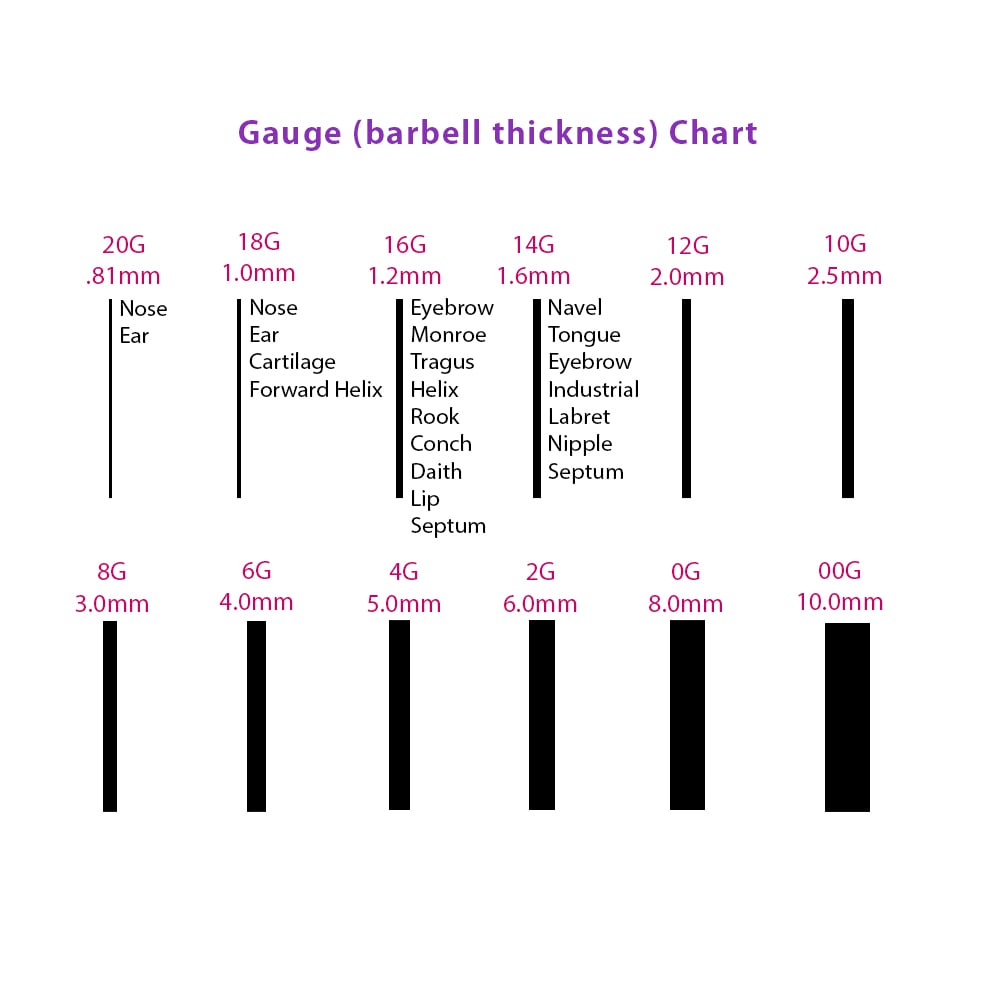

Body Piercing Size Guide FreshTrends

Understanding the Inverse Relationship

2. Why is Bigger Smaller? (And Other Philosophical Questions)

Alright, let's tackle the heart of the confusion: why does a larger gauge number mean a smaller thing? As mentioned before, its all about the historical manufacturing process. Imagine you're making wire back in the day. You start with a thick piece of metal and pull it through a series of progressively smaller holes in a draw plate. Each pass makes the wire thinner.

So, a gauge of 20 means the wire has been pulled through the draw plate more times than a gauge of 10. More pulls equals thinner wire. Therefore, 20 gauge is smaller than 10 gauge. Its like saying something took "more effort" to make smaller. The "effort" being the number of passes through the plate.

This inverse relationship applies across different materials, but its essential to remember that different types of gauges exist! American Wire Gauge (AWG) is the most common for electrical wires, but sheet metal and needles might use completely different systems. We'll cover those differences later on.

In essence, understanding the inverse relationship is the key to unlocking the gauge size mystery. Embrace the counterintuitive nature of it, and youll be reading gauge sizes like a pro in no time!

What Is Wire Gauge?

Gauge Charts

3. Decoding the Numbers

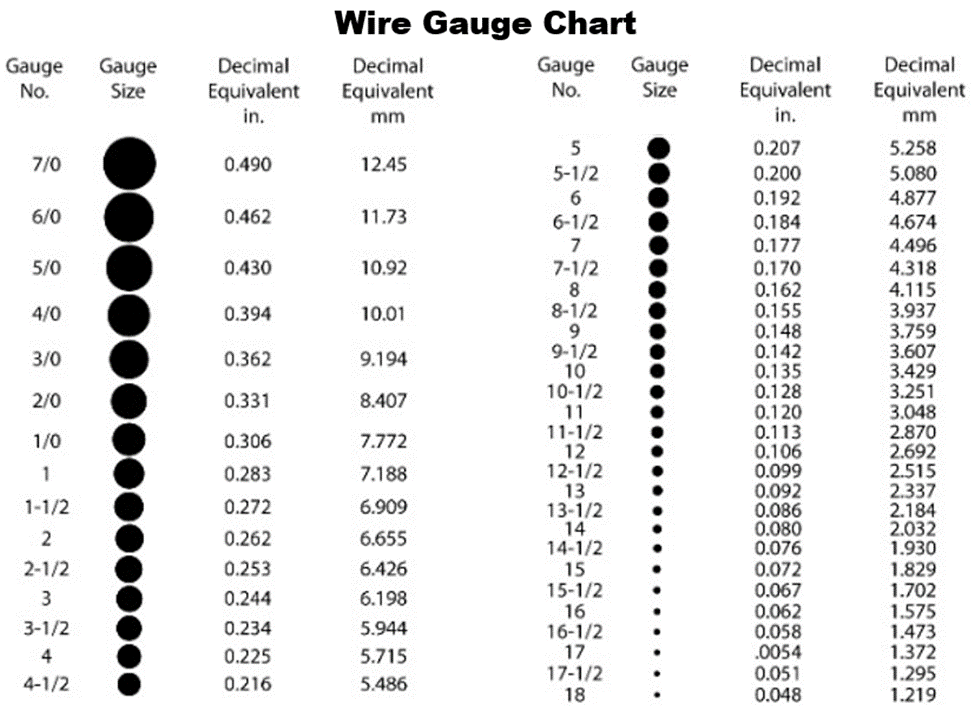

Okay, so you know that higher gauge numbers mean smaller sizes, but how do you actually know the exact diameter or thickness? Enter the gauge chart! These charts are your trusty sidekicks in the world of gauges. They provide a handy reference, listing the gauge number alongside the corresponding measurement (usually in inches or millimeters).

Gauge charts vary depending on the type of gauge (AWG, sheet metal gauge, etc.). Make sure you're using the correct chart for the specific material you're working with. A quick search online for "AWG chart" or "sheet metal gauge chart" will yield plenty of options. You can even find printable versions to keep in your workshop or toolbox.

Using a gauge chart is simple. Find the gauge number you're interested in, and then look across the chart to see the corresponding diameter or thickness. For example, an AWG chart will tell you that 12 gauge wire has a diameter of approximately 0.0808 inches. It's as easy as matching numbers on a table!

Pro tip: When using gauge charts, always double-check the units of measurement. Some charts might use inches, while others use millimeters. Pay close attention to avoid any size-related mishaps. Furthermore, different AWG standards exits and sometimes will yield slightly different results.

Different Types of Gauge Systems

4. Not All Gauges Are Created Equal!

As we've hinted at, not all gauge systems are the same. American Wire Gauge (AWG) is the most prevalent for electrical wiring in North America, but it's not the only player in the gauge game. Other systems exist for various materials and applications. It's crucial to know which system you're dealing with to avoid confusion.

For example, sheet metal often uses its own gauge system, which is different from AWG. Needle sizes (sewing, medical) also have their unique systems. Understanding the context is key. Imagine trying to use a recipe written in Celsius when you're used to Fahrenheit — a recipe for disaster (pun intended)!

When working with a specific material, always research the appropriate gauge system. This will save you from ordering the wrong size or making costly mistakes. Many manufacturers will specify the gauge system used in their product descriptions. Look for abbreviations like AWG, SWG (Standard Wire Gauge — mostly used in the UK), or simply "gauge" followed by a number.

The key takeaway here is to be aware of the different gauge systems and use the correct chart or reference for the material you are using. Do a quick internet search to confirm which gauge you should be looking at to make sure you have the right information and get the right product you want.

Practical Applications of Gauge Knowledge

5. From Wiring Your House to Choosing the Right Needle

Now that you understand the basics of gauge sizes, let's explore some practical applications. Knowing how to read gauge sizes is essential in various fields, from electrical work to sewing to jewelry making. Having an understanding how gauge sizing works will help you buy the right materials and not waste money on the wrong items.

In electrical work, choosing the correct wire gauge is critical for safety and performance. Using a wire that's too thin can overload the circuit and create a fire hazard. In sewing, selecting the appropriate needle gauge ensures smooth stitching and prevents damage to the fabric. In jewelry making, gauge sizes determine the thickness of wires and sheet metal used for creating intricate designs.

When selecting wire for an electrical project, consult the National Electrical Code (NEC) or a qualified electrician to determine the appropriate gauge for the amperage and voltage requirements of the circuit. For sewing projects, refer to a needle chart that recommends the correct needle gauge for different types of fabric. In jewelry making, experiment with different gauges to achieve the desired aesthetic and structural integrity.

So, there you have it! Armed with this knowledge, you can confidently navigate the world of gauge sizes and make informed decisions in your DIY projects, professional endeavors, and everyday life. No longer will you be intimidated by those mysterious numbers. You're now a gauge-size guru!

Everything You Need To Know About Wire Gauge Sizes

FAQ

6. Your Burning Gauge Questions, Answered!

Still got questions about gauge sizes? You're not alone! Here are some frequently asked questions to further clarify the topic:

7. Q

A: Sadly, no. Different materials and applications have their own gauge systems. American Wire Gauge (AWG) is common for electrical wiring, but sheet metal, needles, and other materials often use different systems.

8. Q

A: A quick online search for "[material] gauge chart" (e.g., "AWG gauge chart," "sheet metal gauge chart") will yield plenty of options. Look for charts from reputable sources, such as engineering websites or manufacturing associations. Make sure you also check the standard too.

9. Q

A: Using the wrong gauge size can have serious consequences. In electrical work, it can lead to overheating and fire hazards. In sewing, it can damage the fabric or break the needle. Always consult the appropriate standards or guidelines to ensure you're using the correct gauge size.

10. Q

A: Generally, the larger the gauge number (smaller wire diameter), the less current the wire can safely carry. Thicker wires (smaller gauge numbers) can handle higher currents without overheating. Use appropriate AWG chart, for example, with a safe amphere current to prevent electrical hazard.