Awesome Tips About What Does The Data 300V, 500V, Or 600V, 1000V Mean

DC30V50V60V100V120V150V220V300V500V600V800V3A5A6A10A.jpg

Decoding Voltage Ratings

1. Understanding Voltage in Simple Terms

Ever glanced at an appliance, a wire, or even a battery and noticed numbers like 300V, 500V, 600V, or even a whopping 1000V? These aren't random digits pulled out of thin air. They are voltage ratings, and understanding them is crucial for safety and ensuring your electrical systems function correctly. Think of voltage like water pressure in a pipe—it's the "push" that makes electricity flow. Higher voltage means more "push."

So, what do these specific numbers tell us? Simply put, a voltage rating indicates the maximum voltage a component or cable is designed to handle safely. Exceeding this rating can lead to insulation breakdown, short circuits, fires, and other unpleasant (and potentially dangerous) situations. It's like putting too much pressure in a pipe; eventually, it'll burst.

Think of it like this: If you have a power cord rated for 300V and you plug it into a 600V outlet (not that you should!), you're essentially asking for trouble. The insulation could break down, causing a short circuit and potentially starting a fire. No one wants that kind of excitement!

Therefore, paying attention to voltage ratings is not just some boring technical detail; it's a fundamental aspect of electrical safety and proper equipment operation. It's the difference between a smoothly running electrical system and a potential hazard. Let's dive deeper into what each of these common voltage ratings signifies.

300V 500V 600V FEP/PFA/ETFE/PTFE Insulated High Temperature Wire

300V, 500V, 600V, 1000V

2. Dissecting the Numbers

Now that we know voltage ratings are important, let's break down what these common ratings actually mean in practical applications. The numbers 300V, 500V, 600V, and 1000V each have specific use cases depending on the type of wiring or equipment. These numbers are not arbitrary, but decided through engineering by electrical designer or the organization that control safety standard.

300V: Typically, you'll find 300V ratings on things like appliance cords, control cables, and internal wiring within electronic devices. These are generally for lower-voltage applications where the risk of high-voltage surges is minimal. Think of the cord on your lamp or the internal wires in your computer they often fall into this category. Remember to always check the manufacturers ratings to ensure that the cable meet the minimum safety standard.

500V & 600V: These ratings are more common in industrial and commercial settings. 600V rated wires are frequently used for building wiring, machine wiring, and power distribution within equipment. For example, the wire running from your circuit breaker to your outlets might have a 600V rating. The 500V rating might be used in European and some industrial standards as well.

1000V: This higher rating is usually reserved for high-voltage applications like solar panel wiring, electric vehicle charging cables, and certain types of industrial machinery. These applications require robust insulation to handle the higher potential difference. It's the kind of voltage rating you'd expect to see in systems designed to handle substantial power.

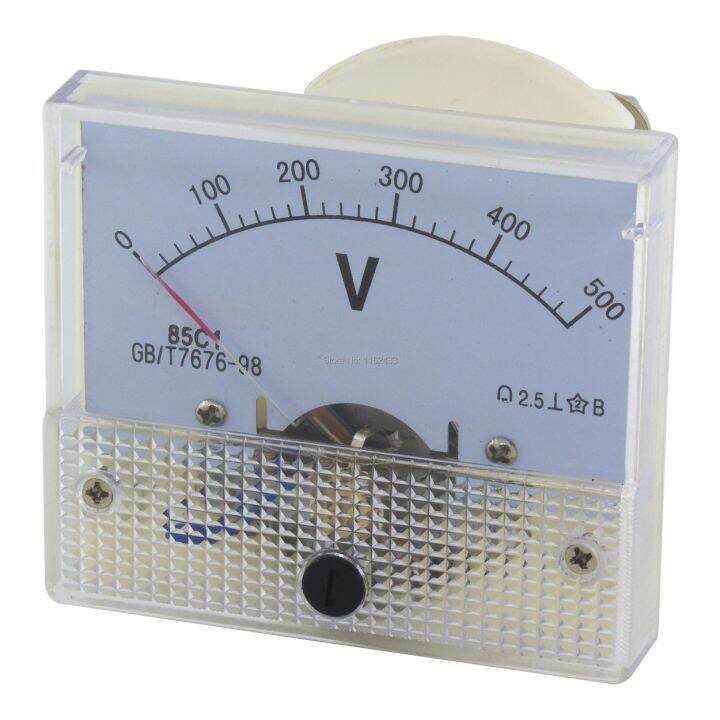

5 Standard Voltmeter Analog Panel Pointer Volt Voltage Meter

The Crucial Role of Insulation

3. Insulation

The voltage rating of a wire or cable isn't just about the conductor itself; it's intrinsically linked to the quality and thickness of the insulation surrounding that conductor. The insulation is what prevents the electricity from escaping and causing a short circuit or shock. The higher the voltage rating, the better and more robust the insulation needs to be. Poor insulation means electricity may jump from one conductor to another which is not desired.

Different insulation materials offer varying levels of protection. Common materials include PVC (polyvinyl chloride), XLPE (cross-linked polyethylene), and rubber compounds. Each material has its own advantages and disadvantages in terms of temperature resistance, flexibility, and dielectric strength (the ability to withstand electrical stress). The material choices are important to consider when considering what is the environment where the cable will be exposed.

For example, a 300V rated appliance cord might use a thinner layer of PVC insulation, while a 1000V rated solar panel cable would likely employ a thicker layer of XLPE for superior insulation properties. The reason is the environment, in general solar panel are outdoor, and can be exposed to ultraviolet (UV) ray from the sun, which PVC is weak against it. The choice of insulation directly affects the cable's ability to safely handle the specified voltage.

Therefore, when inspecting wires and cables, always check for any signs of damage or degradation to the insulation. Cracks, cuts, or discoloration can indicate that the insulation is compromised and the wire should be replaced immediately. A compromised insulation can lead to dangerous situation.

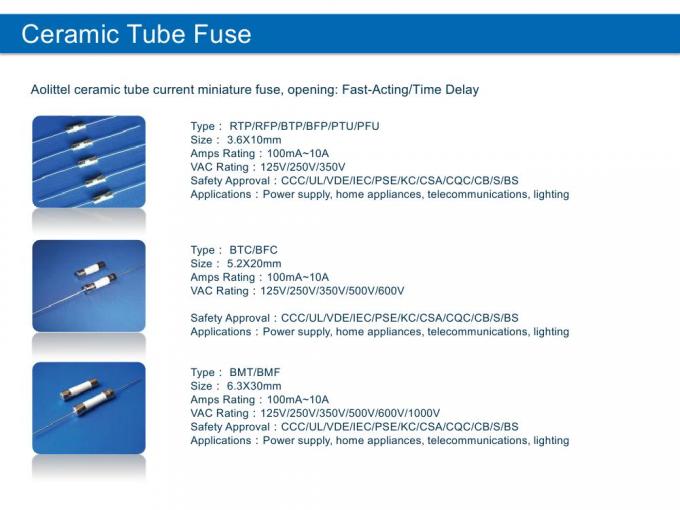

Fast Acting Cartridge Type Ceramic Tube Fuse 6x32mm 3AB 300V 500V 600V

Why Voltage Ratings Matter

4. Staying Safe and Avoiding Electrical Mishaps

Ignoring voltage ratings can have serious consequences. Using a cable with an insufficient voltage rating for a particular application can lead to overheating, insulation breakdown, short circuits, and even fires. These issues not only pose a safety risk but can also damage equipment and disrupt operations. So, paying attention to these numbers is a no-brainer when it comes to safety.

Consider this scenario: You're wiring up a new high-powered workshop tool and decide to use some old extension cord wire you found in the garage. If that wire is only rated for 300V, and the tool requires a 600V rated wire, you're creating a potential fire hazard. The wire could overheat, the insulation could melt, and you could end up with a very unpleasant surprise (and potentially a visit from the fire department).

Proper voltage ratings also ensure optimal performance. Using the correct type of wire and cable minimizes voltage drop, which is the loss of voltage along the length of the conductor. Excessive voltage drop can cause equipment to malfunction or operate inefficiently. It's like trying to run a marathon with shoes that are two sizes too small — you might finish, but it won't be pretty.

Ultimately, understanding and adhering to voltage ratings is a fundamental aspect of electrical safety and responsible equipment operation. It's about ensuring that your electrical systems are not only functional but also safe and reliable.

Matching Voltage Ratings to the Task at Hand

5. Choosing the Right Cable for the Job

So, how do you ensure you're using the correct voltage rating for a specific application? The first step is to consult the equipment manufacturer's specifications. These specifications will clearly state the required voltage and amperage for the equipment. This is your definitive guide.

Next, check the voltage rating of the wires and cables you plan to use. This information is usually printed directly on the cable insulation. Make sure the cable's voltage rating meets or exceeds the equipment's voltage requirement. It's always better to err on the side of caution and use a cable with a higher voltage rating than necessary.

Consider the environment where the wire or cable will be used. Outdoor applications, for example, may require cables with UV-resistant insulation. High-temperature environments may necessitate cables with specialized insulation that can withstand extreme heat. The operating environment will dictate whether you need special temperature rating cables such as THHN, XHHW, or SIS.

If you're unsure about the correct voltage rating for a particular application, consult a qualified electrician. They can assess the situation and recommend the appropriate type of wire or cable to ensure safety and optimal performance. When in doubt, seek professional advice!

Jual Panel Meter SMC/Voltage (Volt Meter) BE96 AC 300V 500V 600V

FAQ

6. Your Questions Answered

Let's tackle some common questions about voltage ratings to solidify your understanding.

Q: What happens if I use a wire with a lower voltage rating than required?A: Using a wire with a lower voltage rating can lead to overheating, insulation breakdown, short circuits, and even fires. It's a dangerous practice that should be avoided at all costs. Imagine it like this: using a drinking straw for a fire hose.

Q: Can I use a wire with a higher voltage rating than required?A: Yes, using a wire with a higher voltage rating than required is perfectly acceptable and often recommended. It provides an extra margin of safety and ensures that the wire can handle any potential voltage surges. Think of it as adding extra insurance.

Q: Where can I find the voltage rating of a wire or cable?A: The voltage rating is usually printed directly on the cable insulation. Look for a series of numbers followed by the letter "V" (e.g., 600V). It's usually near other wire information such as AWG size, material type, and manufacturer information.